From Dave Porter, Customer and Tech Support at The Bonneville Shop

I have always admired the Norton Commando series of motorcycles,

not only because of the iconic look of the petrol tank logo, but also the forward-thinking engineering. Compared to the somewhat stodgy styling of the Atlas, the Commandos oozed sex appeal, with a forward-canted engine unit, upswept silencers, sports mudguards, and multiple model offerings. While the Atlas “featherbed” frames are widely sought after by custom builders for their stable handling characteristics, the Commando chassis is the engineering marvel that established the Commando models as the unofficial elite leader of the British vertical twin-cylinder motorcycle hierarchy.

Commandos were produced from 1967 through 1977, although the last official model year was the MK3 model introduced for the 1975 season. The early Commandos were embraced not only by the buying public, but by publications such as the Motor Cycle News, which awarded the “Machine of the Year” to the Norton Commando for five successive years between 1968 and 1972. All told, there were around 60,000 units produced in total.

The story of the Commando begins with the bankruptcy of Associated Motor Cycles in 1966. When the firm was purchased by Manganese Bronze Holdings, Norton-Villiers was formed and chairman Dennis Poore set a deadline for a new design to replace the aging 750cc Atlas to debut at the 1967 Earls Court motorcycle show. The lineage of the Atlas engine went back to the original Bert Hopwood-designed 497cc Model 7 from 1947.

The first of the new Norton Commandos to roll off the assembly line were Fastbacks, with a forward-slanted Atlas 750cc engine, Roadholder front forks, bulbous Atlas silencers, and a curious fiberglass tail section which served as the platform for the seat. While the styling was decidedly competition-derived, perhaps the most innovative aspect of the Commando design was the new frame/engine/gearbox and swinging arm mounting system, known as the Isolastic Suspension System. While the new rubber-mounted drivetrain was unique and contributed to the “superbike” mystique, one had to look closely to appreciate the engineering innovation, especially in light of the somewhat distractive (but brilliant) marketing strategy employed by Norton-Villiers.

The iconic “Norton Girl” magazine advertisements that commenced with the 1970 model year splash in Cycle World magazine featured the lovely Vivien Neves, the original Norton Girl. The subsequent ads were heralded with titles that hinted sexual innuendos such as “fulfillment”, “rideability”, “go far faster”, and “temptation”. Make no mistake, this was a man’s motorcycle, and the adverts were designed to capture the imaginations of experienced motorcyclists who could afford to ride the baddest of the best during this time frame.

Now that I’ve got that out of my system, we’ll get back to the design improvements to the Norton Commando. There were many refinements to the inaugural Commando models in subsequent years, all resulting in a continuously improved motorcycle, but the suspension and powerplant layout stands out more to me than the final changes that evolved and made their way to the MK3 models, such as electric start, left-side gearchange, rear disc brakes, and annular discharge silencers. The vibration that plagued the Dominator and Atlas models had to be dealt with to maximize the power from the big 750cc, and later 850cc engines.

Dr. Stephan Bauer headed the design team in charge of coping with the vibration issues generated by the large-displacement engines, and settled on a new frame with a large single top tube and rubber-mounting system for the powerplant. Initially, the isolation of vibration was noticeable to the works riders, but under hard acceleration, the rear engine mounts distorted, causing the chain to jump off the engine sprocket, so further development was needed.

Chief Engineer Bernard Hooper and assistant Bob Trigg set about to ameliorate this by re-arranging the swinging arm mounting points to the engine/gearbox plates, allowing the engine, gearbox, and swinging arm to move as a unit. Another improvement that is well-documented is the modification to the original frames, where the inadequate steering head gussets were replaced with a 1” diameter bracing tube that ran longitudinally under the large top tube, and served as the mounting points for the petrol tank bracket and rubber-mounted head steady assembly.

With the front and rear Isolastic suspension system in place on the revised frame, the Commando chassis was now able to handle the torque generated by the long-stroke 58 horsepower engine without the adverse effects of excessive vibration, however for the Isolastic system to work properly, correct tolerances were required to establish the fine line between too rigid and too sloppy.

Shims were used to achieve the optimal clearance between the mounting caps and bushes on the MK1 and MK2 models. Adding and subtracting shims was a bothersome and time-consuming task but was necessary as excessive clearance could lead to unpredictable handling, as manifested as a “wagging” rear end, especially noticeable on the overrun and under sharp acceleration through curves. When the Isolastic shims were too tight, the vibration returned, and the benefits of the rubber-mounting system were negated.

One of the most significant upgrades to the MK3 models was the Vernier adjustable Isolastic system, which allowed precision adjustments to the front and rear Isolastics by turning the adjusters to achieve the correct clearances. This was a huge upgrade, and it wasn’t long before privateers found ways to modify the original Isolastic assembly to a quickly adjustable condition that didn’t require the significant task of partial Isolastic disassembly and reassembly.

Today, many if not most, Norton enthusiasts that log considerable mileages on their pre-1975 Norton Commandos have converted the original Isolastics to the adjustable MK3 style. Since the rubber mounts will require eventual replacement, the logical choice is to upgrade to the later-style Vernier adjustable Isolastic kits available from Andover Norton. We are proud to offer these genuine Andover upgrade kits for the 1968-1974 models, as well as direct replacement kits for the 1975 MK3 models.

Triumph 500 650 Steering Stem/Triple Tree Center Sleeve Nut Chrome 28TPI PN# 97-2263-2nd

Original price was: $37.80.$30.25Current price is: $30.25.

Triumph Norton BSA Phenolic Tufnol 30mm Carburetor Insulator .062 Thin (1) PN# 70-2968-30mm-2nd

Original price was: $18.66.$15.75Current price is: $15.75.

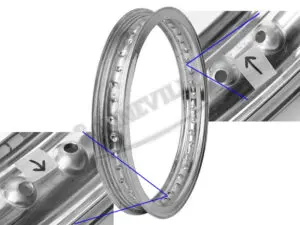

Triumph 750 T160 Trident CWC WM3 X 19-inch 40 Hole Excel Valanced Polished Alloy Rear Rim Disc Brake PN# 37-4243-A-2nd

Original price was: $410.81.$348.50Current price is: $348.50.

The 06-7116 front Isolastic kit is a direct replacement kit for the 1975-later machines, which employs a longer center tube, while the 06-7337 adjustable front Isolastic kit allows for retrofit to the earlier pre-MK3 models. The 06-7117 rear kit is a direct replacement for the MK3 models and can be retrofitted to the 1968-1974 models. So, there you have it…a short story about a series of motorcycles with an enviable mystique. Legend has it that Eric Buell, of Harley-Davidson fame, carefully studied the Norton Isolastic design prior to Harley’s adoption of rubber mounting the engine in Buell’s FXR models.

I hope you have enjoyed reading this article and found it to be useful.