Cylinder bore finish honing is an important step in the preparation of cylinder walls prior to fitting new pistons and rings. The flex-hone provides a fast and efficient final finish of a freshly bored and honed cylinder barrel. This is an indispensable tool for the builder of vintage British 650 and 750 twin-cylinder engines.

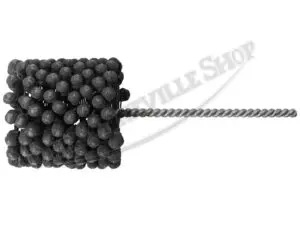

This professional quality flex-hone is sourced from K&L Supply and is sized for 71mm-76mm bores, with coarse 180 grit globules of silicone carbide or aluminum oxide laminated to the ends of bristles on a flexible shaft.

Used correctly, the finish hone provides a consistent cross-hatch pattern for oil retention and quick piston ring seating. The finish honing process is performed after cylinder boring and the final sizing of the bore diameter with a multi-stone hone.

The flex-hone is plunged in and out of the cylinder bore using a drill to establish the cross-hatch pattern. It is important to thoroughly wipe down the bore after finish honing to remove any residual honing grit that may be present. Warm soapy water and a clean cloth is recommended for cleaning the bores.

The product images shown are for illustrative purposes only and may not be an exact representation of the product received. Manufacturers occasionally make minor cosmetic changes to items, such as color, finish, label, or design. These changes do not impact the item’s function or compatibility. Please contact us if you have specific concerns regarding appearance.

Reviews

There are no reviews yet.